SMD line A

The line consists of:

- Bare Board Loader (Asys–VEGO Dynamic BDS 01) with automatic adjustment of PCB width

- EKRA SERIO 4000 stencil printer

- SAMSUNG Pick & Place SM482

- Heller 1707 MK III convection oven

- Unloader VEGO Dynamic AMS 01

- 3 x ASYS VEGO Compact BC0 03 conveyor

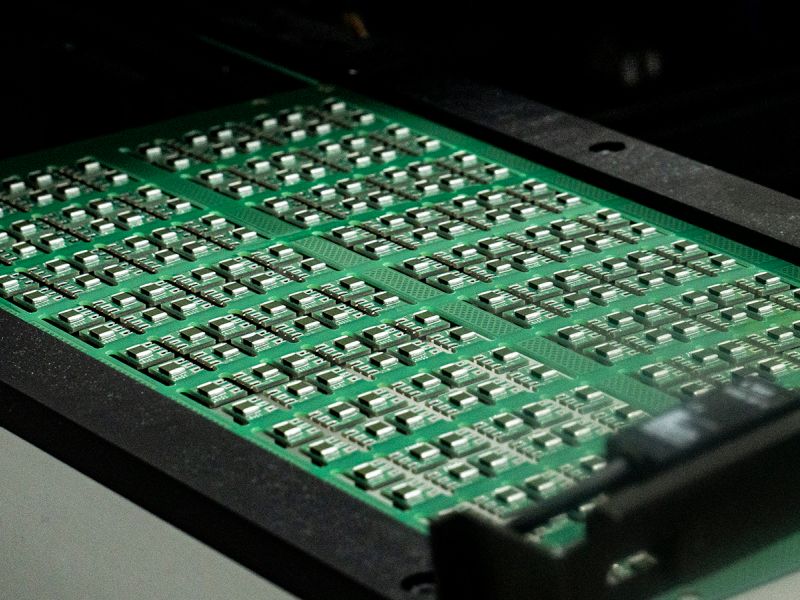

Fully automatic line for the production of SMD modules, with the capacity of 25 000 components per hour. The entry of the line is equipped with an ASYS Bare Board Loader that adds PCB plates to EKRA. EKRA Serio 4 000 is a stencil printer that is fully programmable and has a print optical inspection, optical adjustment of fiducials and automatic cleaning. The print format is 600 x 400 mm. All line elements are connected with ASYS conveyor which transfers PCB plates to SAMSUNG SM482 Pick & Place, HELLER 1707 MK III and ASYS Unloader.

SAMSUNG SM482 has 6 heads and a maximum speed of 35 000 components per hour. It places components from 0201 to 75mm connector and can make extra-large PCB format from 1200 x 600mm. The components are soldered to PCB plates in the convection oven HELLER 1707 MK III which has 7 heating and 2 cooling areas with a transporter chain width up to 450mm. After that the PCB plates pass the optical and electronic inspection, they are stored in the ASYS Unloader which is programmable and adaptable to all kinds of magazines.

Other DATA LINK services

Custom machines design & production processes

Data Link’s team of experts has extensive knowledge of various complex technological processes in high end production. During the existence of the company for 30 years, we have developed a large...

Electronics design

DATA LINK has been successfully working for years on the development of various electronic devices that are built into our solutions. We are able to meet even the most complex requirements and the...

Design of embedded LED drivers

Since we produce special LED lighting for the needs of our products we have developed and manufactured a full range of special embedded LED drivers. The drives are integrated in the LED modules, which...

Design of LED Modules

We develop and produce full LED modules on aluminum or FR4 substrates for our users, according to special demands. Construction includes all necessary solutions, ranging from designing electronic...

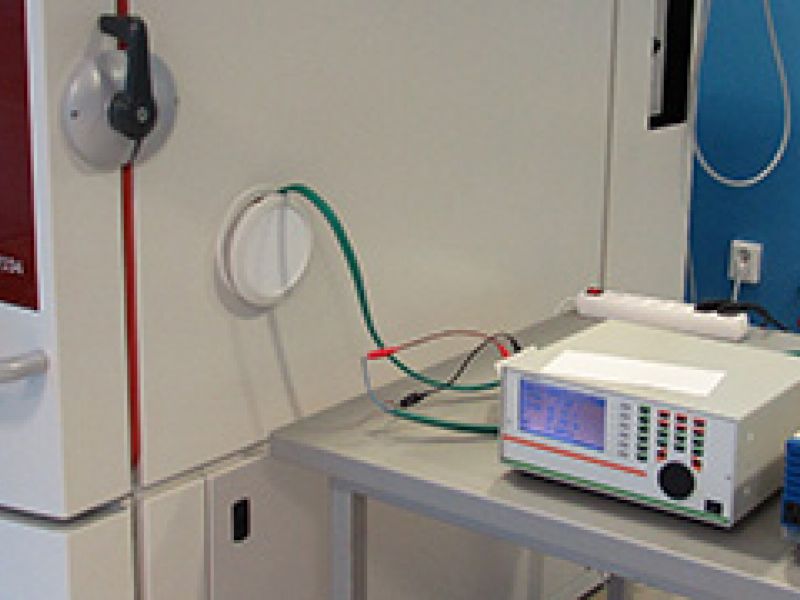

Votsch VC3 7034 (climatic chamber)

Votsch climatic chamber is a part of our laboratory equipment The chamber capacity is 335 l with the possibility of temperature and humidity control. Humidity control possibility ranges from 10 –...

Preservation and storage of electronic components

All electronic components which are sensitive to moisture are kept and stored in the Super Dry cabinet SD + 1006-22 with humidity control 0-60%, and the possibility of component drying to a...

The laser marking line

The laser marking line operates in a way that after the installation, soldering and accuracy testing of PCB plates (optical and electrical) process, plates are hand-laid into an adjustable stand and...

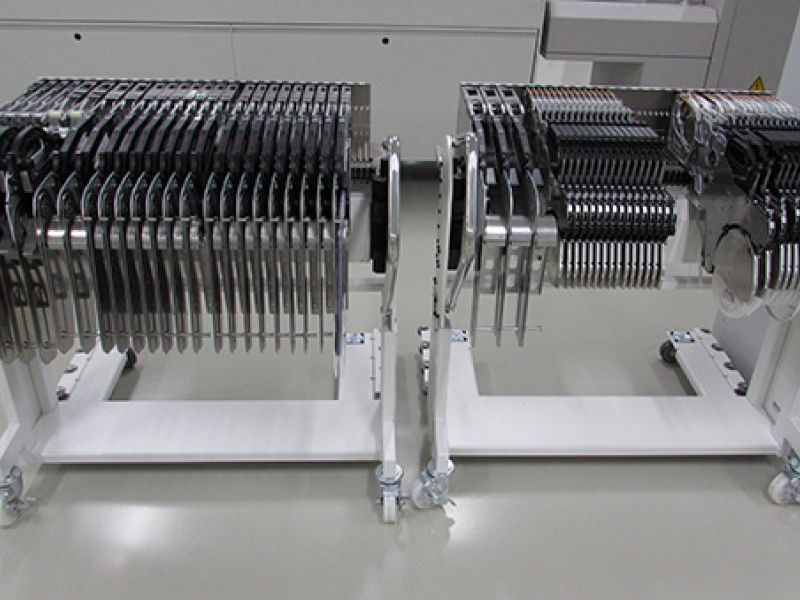

SMD line B

The line consists of: Magazine Loader (Asys – VEGO Dynamic AES 01) EKRA SERIO 4000 stencil printer SAMSUNG DECAN F2 HELLER 1809 MK5 PARMI AOI Unloader VEGO Dynamic AMS 01 2 x ASYS VEGO...

SMD line A

The line consists of: Bare Board Loader (Asys–VEGO Dynamic BDS 01) with automatic adjustment of PCB width EKRA SERIO 4000 stencil printer SAMSUNG Pick & Place SM482 Heller 1707 MK III...