LED Modules on demand

We develop and produce full LED modules on aluminum or FR4 substrates for our users, according to special demands.

Construction includes all necessary solutions, ranging from designing electronic schemes, creating the layout of Printed Circut Boards (PCB), to optical design, electronic and thermal analysis and highly serial production of LED modules.

In our own light technology laboratory, we conduct measurement and analysis of LED modules for the following characteristics:

- EMC analysis in the sense of generating interference in the electromagnetic spectrum, both for DC or AC construction of LED modules.

- Measuring all electrical characteristics of the module using high precision equipment.

- Thermal analysis of the entire LED module and luminaire, with measurements of technical conductibility and LEDs’ thermal conductivity and junction temperature.

- Analysis of LED modules’ behavior at high environmental temperatures, with or without refrigerator or light fixture.

- Measuring the module lumen output in normal operating conditions and at higher temperatures, both with and without secondary optics.

- Photogoniometric measurement of spatial distribution of the LED module and creating the appropriate IES file for use with light technology calculations.

- Spectrophotoradiometric measurement of the entire module or LEDs itself.

Using our two fully automated high-capacity SMD lines, we are able to produce a large series of LED modules, with two soldering processes; the standard Reflow technique and the special Vapor Phase welding procedure in strictly controlled temperature conditions. We can produce linear LED modules up to 1200 mm in length, and both lines’ capacity exceeds 80.000 components per hour.

Other DATA LINK products

NTC measurement

The reconstructed ESI Multi-Function Tester Model 3300A automatic device for process measurement and sorting of SMD NTC resisters, in accordance with User Requirement Specification for ESI3300A...

Varistor Measurement

We have restructured the ESI Multi-Function Tester Model 3300A automatic device for SMD condenser measurement and sorting into an automatic device for process measurement and sorting of SMD varistor...

Pulse Source Meter

It is suitable for use on automatic component sorting and packaging lines. The instrument integrates a 3kW programmed power impulse source with a very precise and fast voltmeter. It is intended for...

Light Photogoniometer

The devices is based on the software platform LabVIEW and is fully programmable. The basic purpose is creating IES and LDT files used for light technology calculation in tools such as Dialux, Relux...

LED Modules on demand

Construction includes all necessary solutions, ranging from designing electronic schemes, creating the layout of Printed Circut Boards (PCB), to optical design, electronic and thermal analysis and...

Down light - Flush mount ceiling lamp

The lamp is made in unique, patented planar, AC technology. The AC technology has made it possible that this lamp has a minimum of components with no electronic parts susceptible to aging....

Combo Search Light

This product is unique because in one housing there are both visible and IR light sources. It provides high intensity LED performance of 410.000cd, with the addition of Infrared (IR) Illuminators for...

Ex GalaLED - Explosion proof work lighting

The lamp is designed for use in the marine, shipbuilding, ship repair, and offshore industries, both for indoor and outdoor spaces. It can be used as portable, temporary Explosion-proof lighting and...

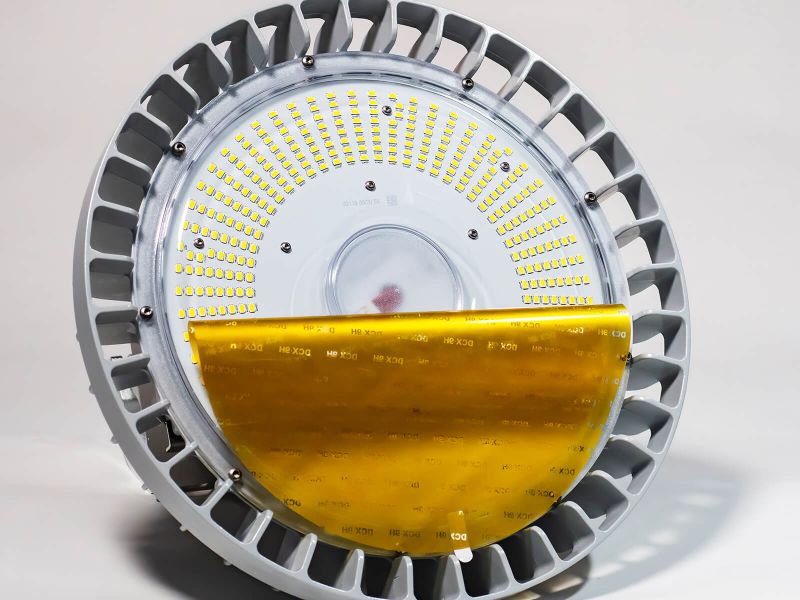

High Bay 380 - Industrial LED lighting

High Bay 380 is suitable for interior and exterior use. It is dust and water droplet resistant and does not require standard maintenance measures. The lamp generates significant power consumption...

Marine LED Floodlight - Drydock lighting

In addition to its outstanding power, endurance and safety, the key advantage of the Marine LED Floodlight is an 8 times higher energy efficiency compared to classic incandescent lighting, which...

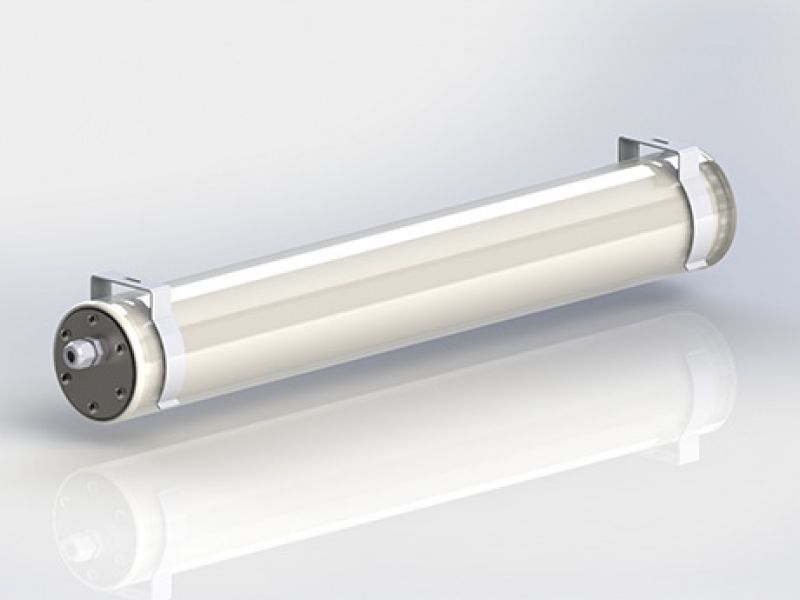

SEAL - Dock lighting

It is made out of high quality non-corrosive materials - PMMA, ABS, polycarbonate and stainless steel and it meets the IP67 and IK10 protection requirements. The lamp is watertight and designed to...

GalaLED - Shipbuilding and ship repair work lighting

Due to its low, safe operating voltages - 24VAC, 42VAC, 110VAC/VDC and 24 VDC all GalaLED lighting models can reliably and safely be used during various technological phases and work processes -...