PCBA assembly - Services

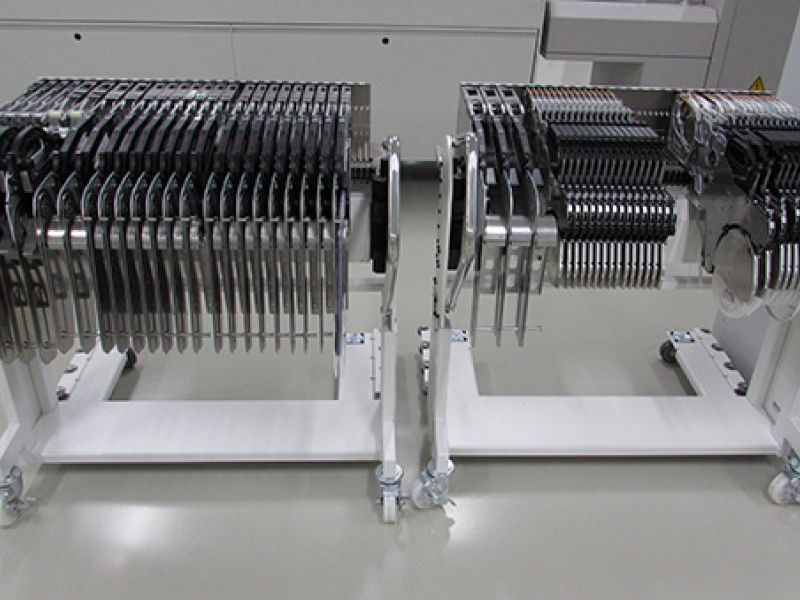

SMD line A

The line consists of: Bare Board Loader (Asys–VEGO Dynamic BDS 01) with automatic adjustment of PCB...

SMD line B

The line consists of: Magazine Loader (Asys – VEGO Dynamic AES 01) EKRA SERIO 4000 stencil printer...

The laser marking line

The laser marking line operates in a way that after the installation, soldering and accuracy testing of PCB...

Preservation and storage of electronic components

All electronic components which are sensitive to moisture are kept and stored in the Super Dry cabinet SD +...

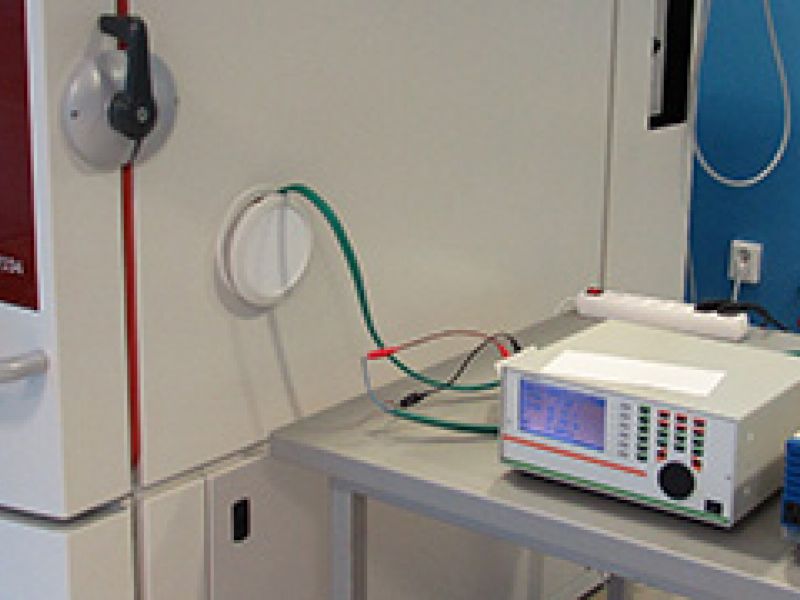

Votsch VC3 7034 (climatic chamber)

Votsch climatic chamber is a part of our laboratory equipment The chamber capacity is 335 l with the...